LNG pump/Cryogenic pump

LNG pump/Cryogenic pump

LNG Pump Features

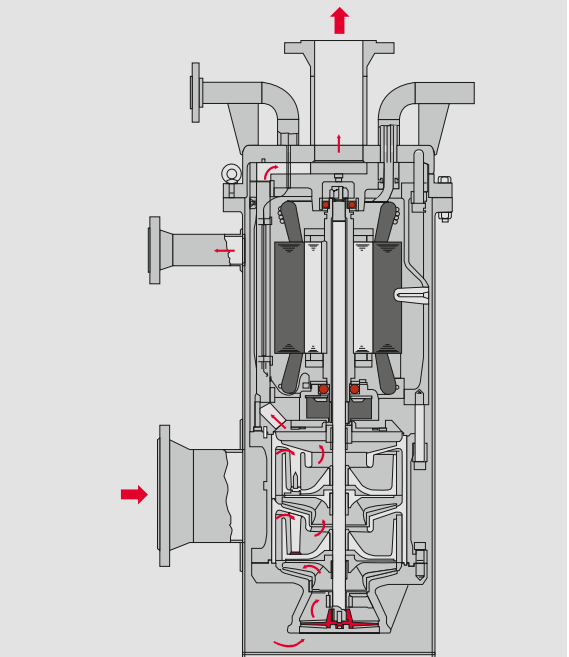

The unit is a submerged motor cryogenic pump that transports liquefied gases such as LNG and LPG.

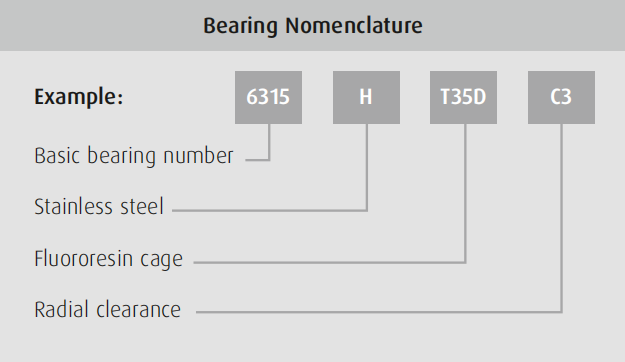

Main bearing codes

1)Deep Groove Ball Bearings

| Description | Dimension | Loading(KN) | Speed | ||||

| (r/min) | |||||||

| d | D | B | rsmin | Cr | Cor | ||

| 6205-H-T35D | 25 | 52 | 15 | 1 | 14 | 7.8 | 17000 |

| 6206-H-T35D | 30 | 62 | 16 | 1 | 19.3 | 11.2 | 14000 |

| 6207-H-T35D | 35 | 72 | 17 | 1.1 | 25.5 | 15.3 | 12000 |

| 6208-H-T35D | 40 | 80 | 18 | 1.1 | 29 | 18 | 11000 |

| 6209-H-T35D | 45 | 85 | 19 | 1.1 | 31 | 20.4 | 10000 |

| 6210-H-T35D | 50 | 90 | 20 | 1.1 | 36.5 | 24 | 9500 |

| 6211-H-T35D | 55 | 100 | 21 | 1.5 | 43 | 29 | 8500 |

| 6213-H-T35D | 65 | 120 | 23 | 1.5 | 58 | 41.5 | 7000 |

| 6215-H-T35D | 75 | 130 | 25 | 1.5 | 64 | 48 | 6800 |

| 6217-H-T35D | 85 | 150 | 28 | 2 | 82.5 | 62 | 6500 |

| 6305-H-T35D | 25 | 62 | 17 | 1.1 | 22 | 11 | 22000 |

| 6308-H-T35D | 40 | 90 | 23 | 1.5 | 42.5 | 25 | 11000 |

| 6311-H-T35D | 55 | 120 | 29 | 2 | 76 | 47.5 | 10000 |

| 6314-H-T35D | 70 | 150 | 25 | 2.1 | 102 | 66 | 9000 |

| 6318-H-T35D | 90 | 190 | 43 | 3 | 132 | 100 | 6000 |

| 6320-H-T35D | 100 | 215 | 47 | 3 | 160 | 130 | 5700 |

| 6322-H-T35D | 110 | 240 | 50 | 3 | 190 | 165 | 5400 |

| 6328-H-T35D | 140 | 300 | 62 | 4 | 255 | 250 | 4000 |

2)Angular Contact Ball Bearings

| Description | Dimension | Loading(KN) | Speed | ||||

| (r/min) | |||||||

| 7205 | 25 | 52 | 15 | 1 | 15 | 9 | 26000 |

| 7206 | 30 | 62 | 16 | 1 | 22 | 14 | 22000 |

| 7207 | 35 | 72 | 17 | 1.1 | 29 | 19 | 19000 |

| 7208 | 40 | 80 | 18 | 1.1 | 30.5 | 21.6 | 17000 |

| 7209 | 45 | 85 | 19 | 1.1 | 39 | 27.5 | 15000 |

| 7210 | 50 | 90 | 20 | 1.1 | 40.5 | 30.5 | 14000 |

| 7305 | 25 | 62 | 17 | 1.1 | 18.3 | 10.6 | 18000 |

| 7306 | 30 | 72 | 19 | 1.1 | 24.8 | 15.4 | 15000 |

| 7307 | 35 | 80 | 21 | 1.5. | 30.6 | 19.6 | 14000 |

| 7308 | 40 | 90 | 23 | 1.5 | 37 | 24.4 | 12600 |

| 7309 | 45 | 100 | 25 | 1.5 | 47.6 | 31.8 | 12000 |

| 7310 | 50 | 110 | 27 | 2 | 54.6 | 39.2 | 10000 |

Application:

Bearing picture:

Testing ways:

Main features

The automatic axial thrust balance mechanism creates less load on the ball bearing for a prolonged service life.

High pump efficiency due to reduced internal leakage.

Easy maintenance and reliable pump performance with LNG or LPG tested equipment.

Applications

LNG is a clean and important energy source in terms of environmental issues. This pump is used in a wide range of fields, mostly centering on energy industries.

LNG feed and booster pump for LNG land-based terminal

Booster pump for gas turbine co-generation system

LPG transfer pump for LNG calorie adjustment

LNG feed pump for Bunkering/CNG station

Previous: Oil drilling

English

English Russian

Russian Chinese

Chinese