GAMET TAPERED ROLLER BEARING

Gamet bearings consist of four basic components –the inner race (cone), the outer race (cup), tapered

rollers and cage. The cone, rollers and cage form an assembly which is separable from the cup.

PRINCIPLES OF GAMET TAPERED ROLLER BEARINGS

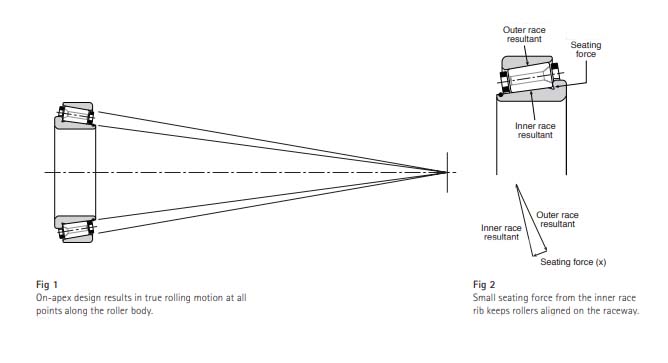

The geometry of tapered roller bearings provides certain unique features: most importantly, the long line contact between roller and race gives high load carrying capacity and high bearing stiffness. The ‘on apex’ design ensures a true rolling motion of the rollers on the raceways, at every point along the roller body. See Fig 1. In addition, the tapered construction allows the bearing to carry combinations of radial and thrust load. The small seating force (x) produced at the rib aligns the rollers to prevent skewing.

See Fig 2.

Other specific features of Gamet tapered roller bearings include:

Precision – Gamet bearings are manufactured only in a high precision class.

Hollow Rollers – This assists the flow of lubricant through the bearing to provide cooling.

Roller Roundness and Calibration – A true roundness of rollers ensures equal load sharing within the bearing and contributes significantly to the overall precision of the bearings. Gamet Rollers are ground between centres to achieve near perfect roundness. Rollers are then calibrated precisely into matched

sets.

Bearing Cage – The cage has a low coeficient of friction. It is guided on the inner race to provide radial stability and is designed to pass sufficient oil across the races to maintain lubrication, the remainder being diverted through the centre of the roller. Depending on rotational speed, grease lubrication may be used as an alternative to oil.

PLAIN CUP TYPE:

The basic single row bearing can be used in light to medium loaded applications, and provides a simple, cost-effective arrangement.

FLANGED CUP (C TYPE)

The flanged cup version enables through boring of the housing for simplicity and accuracy.

Constant preload bearing (P Type)

This single row bearing has an extended outer ring, housing a number of springs.

It is mounted in conjunction with either a single or double row bearing.

As the outer race is free to slide in the housing, the spring force ensures that a constant bearing system preload is maintained despite thermal expansion due to varying temperature conditions.