Bearings for screw drives

Axial angular contact ball bearings Needle roller/axial cylindrical roller bearings(Seal carrier assemblies Precision locknuts)

Overview of Axial angular contact ball bearings

Features

Screw drive bearing arrangements are subjected to requirements that often cannot be optimally fulfilled by the design construction of conventional bearings. In order to design bearing arrangements for the highly dynamic operating conditions in screw drives that have high accuracy, high load carrying capacity, high rigidity, low friction, are easy to fit and maintenance-free or low-maintenance.

With this well thought-out product range, ideal application-specific solutions can now be found to all the technical and economic demands placed on the bearing arrangements of screw drives.

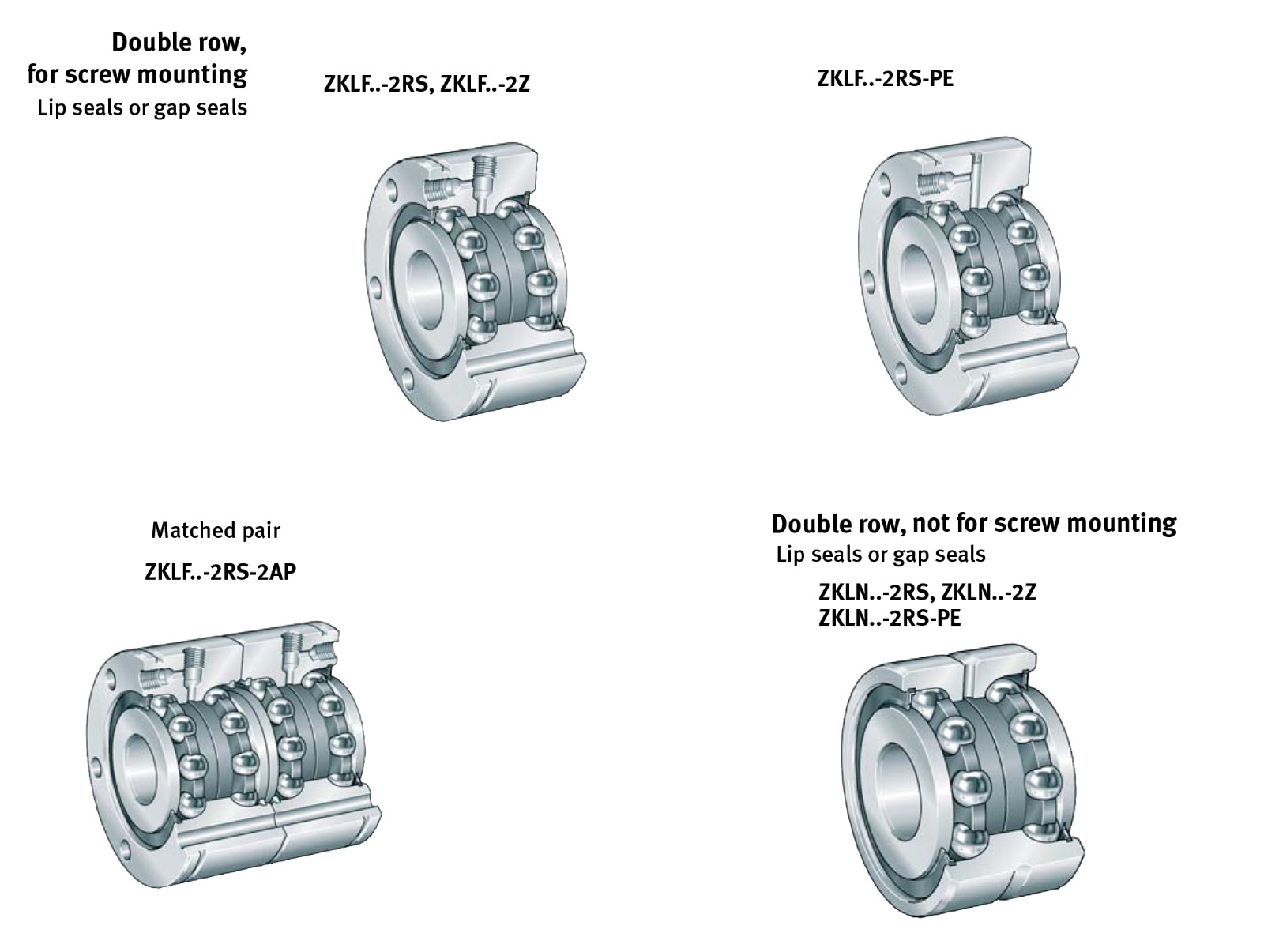

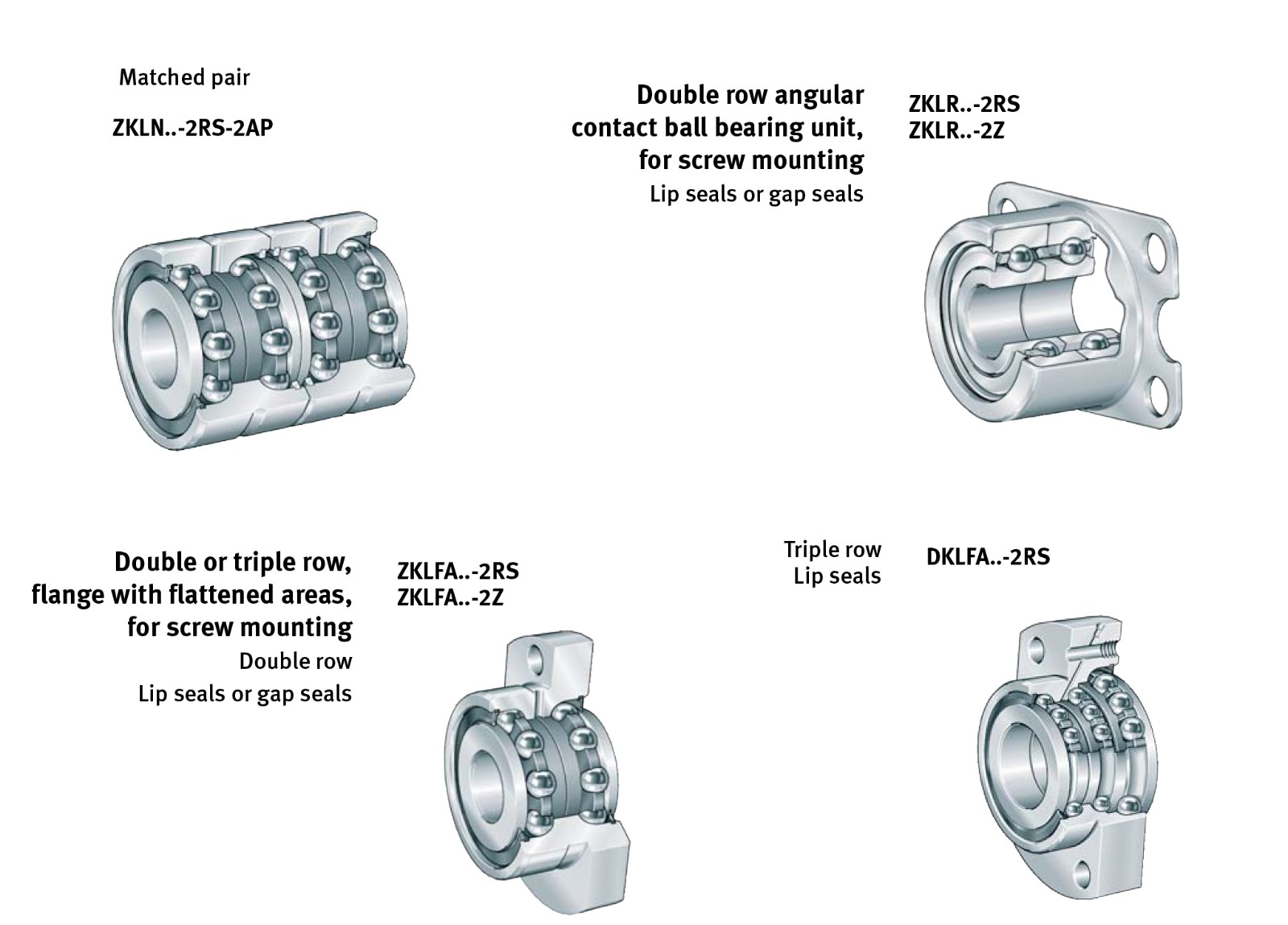

Multi-row designs

Axial angular contact ball bearings are available as single, double or triple row ready-to-fit units. They are self-retaining and comprise thick-walled, geometrically stable outer rings, ball and cage assemblies and one-piece or two-piece inner rings. In several series, the outer ring has through holes for simple flange mounting to the adjacent construction.

The bearing rings are matched to each other such that a defined preload is achieved when the rings are clamped in place using a precision locknut.

Radial and axial load carrying capacity

Due to the 60° contact angle, the bearings can support high axial forces.

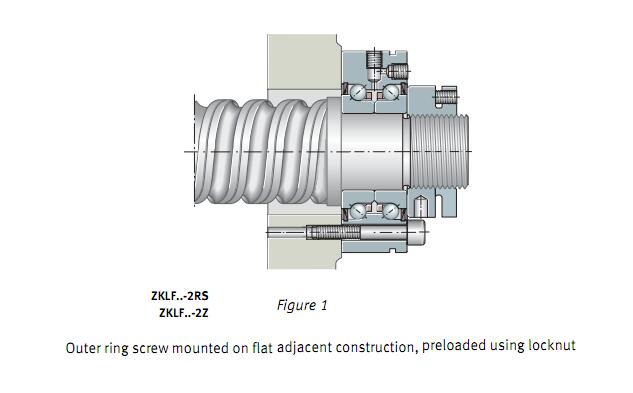

Double row axial angular contact ball bearings, for screw mounting

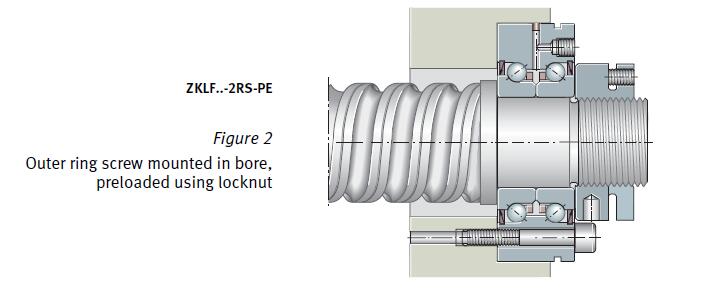

Axial angular contact ball bearings ZKLF are screw mounted directly on the adjacent construction or in a radial locating bore, Figure 1 and Figure 2. The cover that would otherwise be required and

the associated matching work can therefore be dispensed with.

In order to aid removal of the bearings from a locating bore, the outer ring has a circumferential extraction slot.

With less stringent tolerances

Axial angular contact ball bearings ZKLF..-2RS-PE correspond to series ZKLF but have a runout tolerance within P5 , less stringent diameter tolerances and the suffix PE. They are used where a lower positional accuracy is acceptable. As a result, the adjacent construction does not need to be as accurate with

these bearings.

Heavy series

Axial angular contact ball bearings ZKLF..-2RS and ZKLF..-2Z are also available in a heavy series. For the same shaft diameter, they have a larger cross-section and thus higher basic load ratings.

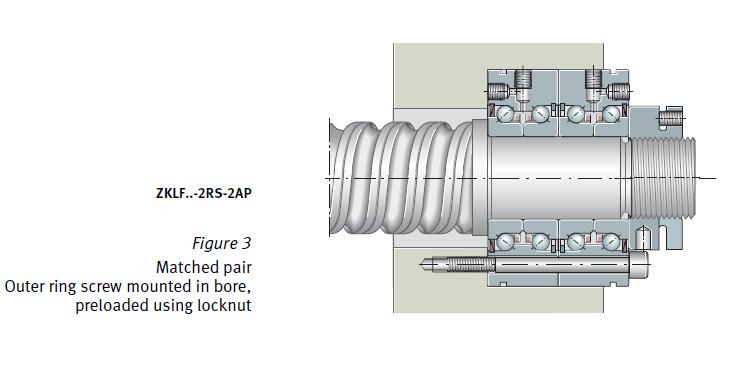

Matched pairs

Bearings of series ZKLF..-2RS-2AP comprise a matched pair of bearings ZKLF..-2RS, Figure 3. The individual bearings are matched to each other.

Matched bearings have an arrow marking on the outside surface of the outer rings. When the bearings are arranged correctly, the lip seals face outwards. During fitting, the hole pattern of the two bearings must match, not the marking.

Sealing/lubricant

Bearings with the suffix 2RS have lip seals and highly effective sealing.

Bearings with the suffix 2Z are sealed using gap seals and are suitable for higher speeds.

The bearings are greased using a lithium soap grease to GA28 and can be lubricated via the lubrication connectors in the outer ring.

For the majority of applications, the initial greasing is sufficient for the whole bearing operating life.

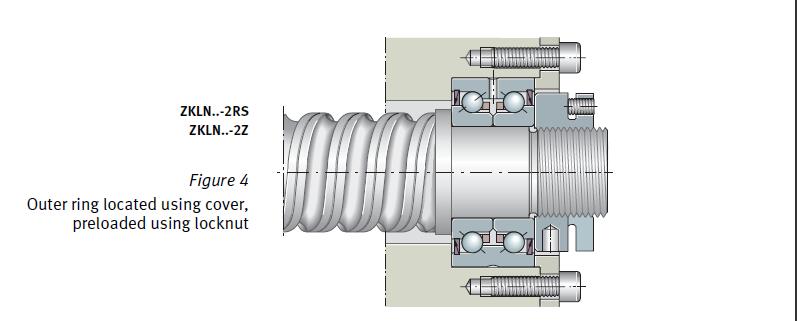

Double row axial angular contact ball bearings, not for screw mounting

Axial angular contact ball bearings ZKLN are mounted in a housing bore, Figure 4. The bearing outer ring is axially located by a cover.

With less stringent tolerances

Axial angular contact ball bearings ZKLN..-2RS-PE correspond to series ZKLN but have a runout tolerance within P5 to DIN 620, less stringent diameter tolerances and the suffix PE. They are used where a lower positional accuracy is acceptable. As a result, the adjacent construction does not need to be as accurate with these bearings.

Heavy series

Axial angular contact ball bearings ZKLN..-2RS and ZKLN..-2Z are also available in a heavy series. For the same shaft diameter, they have a larger cross-section and thus higher basic load ratings.

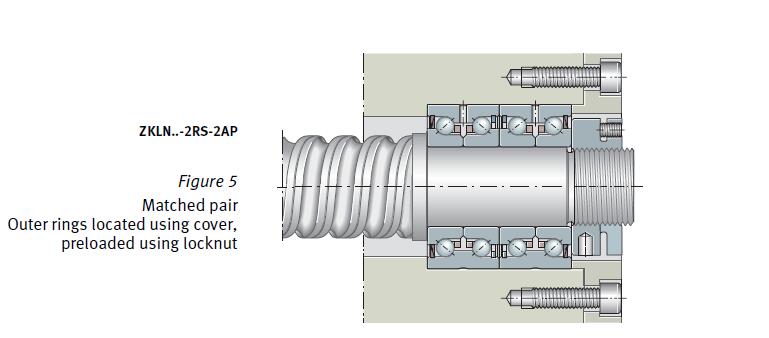

Matched pairs

Bearings of series ZKLN..-2RS-2AP comprise a matched pair of bearings ZKLN..-2RS, Figure 5. The individual bearings are matched to each other.

Matched bearings have an arrow marking on the outside surface of the outer rings. When the bearings are arranged correctly, the lip seals face outwards.

The bearing outer rings are axially clamped by a cover, Figure 5.

Sealing/lubricant

Bearings with the suffix 2RS have lip seals and highly effective sealing.

Bearings with the suffix 2Z are sealed using gap seals and are suitable for higher speeds.

The bearings are greased using a lithium soap grease to GA28 and can be lubricated via a lubrication slot and lubrication holes in the outer ring.

For the majority of applications, the initial greasing is sufficient for the whole bearing operating life.

Operating temperature

Sealed axial angular contact ball bearings are suitable for operating temperatures from –30 °C to +120 °C; this is limited by the grease, seal material and the plastic cages in the ball and cage assemblies.

Cages

The axial angular contact ball bearings have plastic cages. The cage design is not indicated in the suffix.

Suffixes

Suffix Description

PE Less stringent bearing design

T, TVP Polyamide cage, guided by balls

TN Cages made from glass fibre reinforced polyamide 66

2AP Axial angular contact ball bearings, matched pair (ZKLN, ZKLF)

2RS Contact seals on both sides

2Z Gap seals on both sides