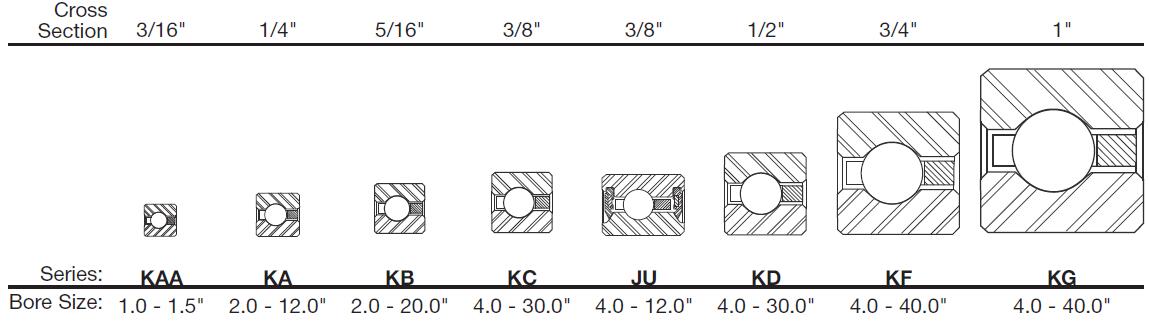

CROSS SECTIONS OF THIN SECTION BALL BEARINGS

THIN SECTION BALL BEARINGS

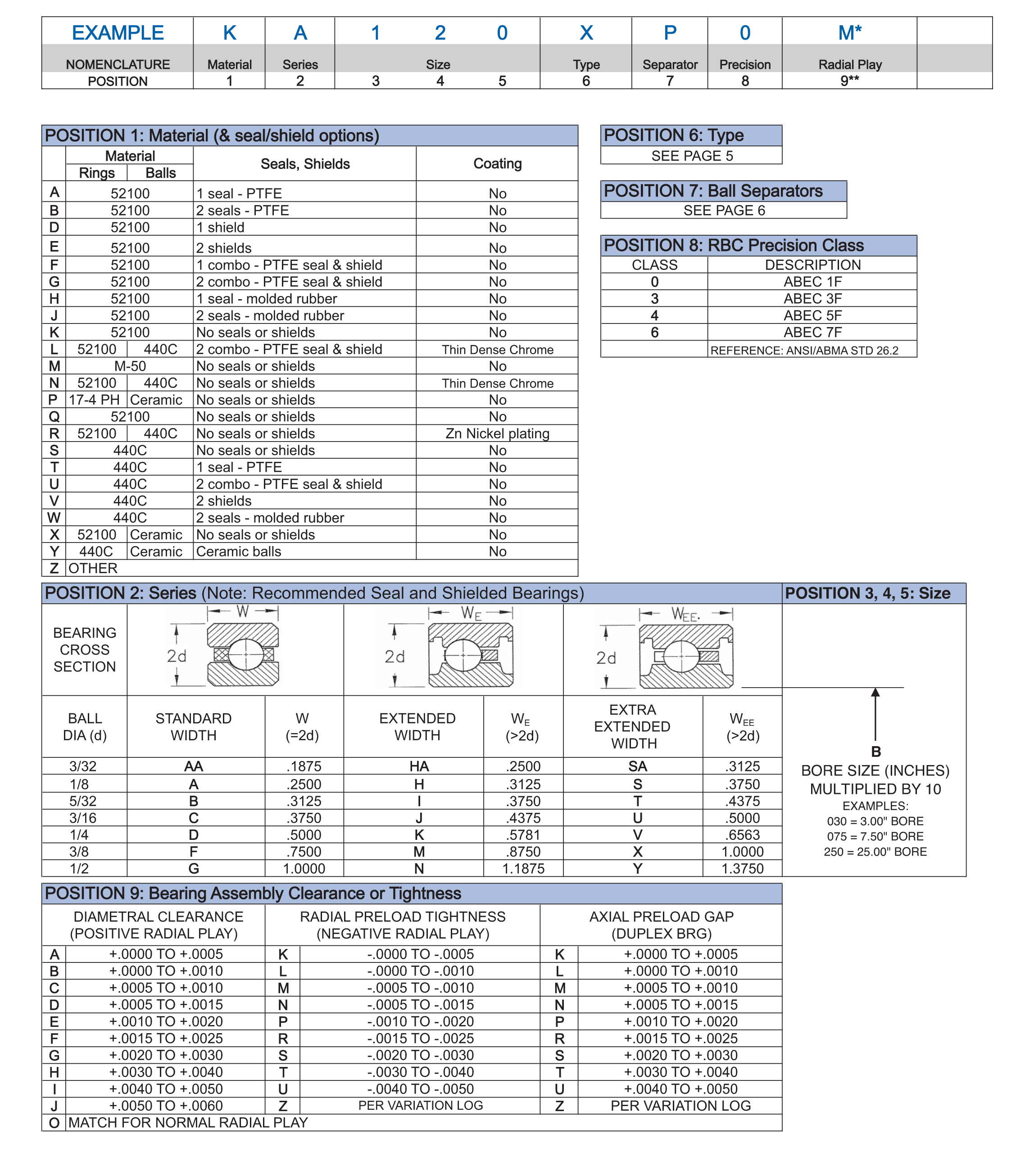

PART NUMBER DESIGNA TION

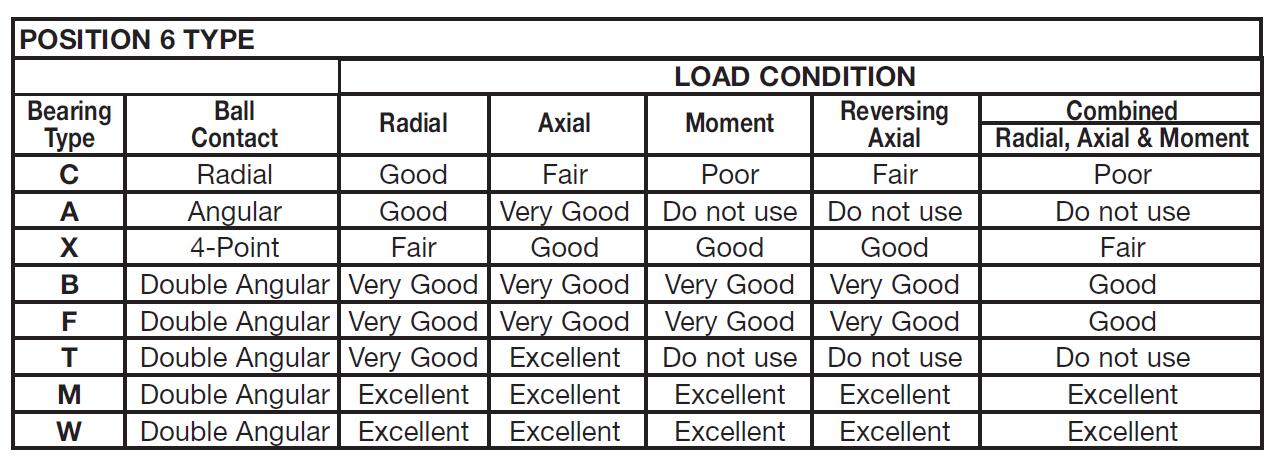

THIN SECTION BALL BEARING SELECTION

THIN SECTION BALL BEARING SELECTION

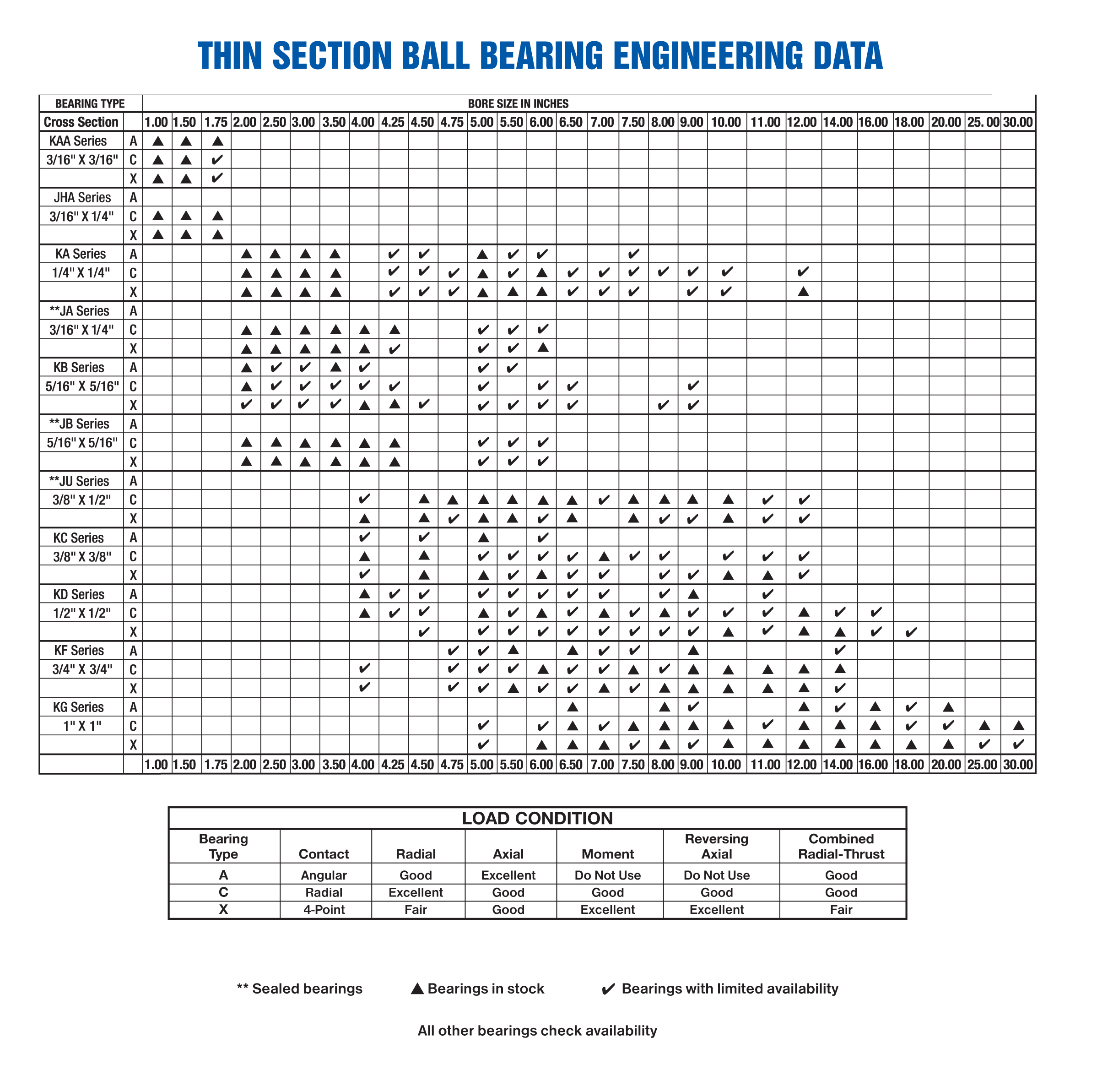

THIN SECTION BALL BEARING ENGINEERING DATA

The methods, equations, and technical data presented in this section allow the user to select the correct

bearings and estimate their performance for a wide range of applications. For applications with severe or

unusual operating conditions, MONTON is prepared to provide an in-depth analysis and recommend the most suitable bearing arrangement.

Where standard bearings cannot be used, MONTON can meet the application requirements with a special bearing design specifically tailored for optimum performance.

Contact ourSales Engineer for special sizes, materials, application requirements, dimensions and tolerances.

Capacity and Fatigue Life of Ball Bearings

The BASIC DYNAMIC RADIAL LOAD RATING, C, or “dynamic capacity”, for a ball bearing is the calculated,

constant radial load at which 90% of a group of apparently identical bearings with stationary outer rings

can statistically endure 106 revolution of the inner ring. ANSI/ABMA Standard 9 with correction factors for race curvatures was used to calculate the catalog ratings.

The DYNAMIC THRUST and DYNAMIC MOMENT LOAD RATINGS are also shown in the product tables. The

ratings shown are a guide for the maximum loads under which these bearings should be operated with either pure thrust or pure moment loading. Thrust ratings are 2.5 to 3.0 times the radial ratings depending on the bearing type and cross section. These load ratings are not additive. For combined radial and thrust loads, an equivalent radial load is to be calculated.

The BASIC STATIC LOAD RATING, Co, or “static capacity”, is that uniformly distributed load, which

produces a maximum theoretical contact stress of 609,000 psi. At this contact stress permanent

deformation of ball and raceway occurs. This deformation is approximately .0001% of the ball diameter.

The RATING LIFE, L10, is a statistical measure of the life which 90% of a large group of apparently identical ball bearings will achieve or exceed. For a single bearing, L10 also refers to the life associated with 90% reliability.

Median Life, L50, is the life which 50% of the group of ball bearings will achieve or exceed. Median life is approximately five times the rating life.The relationship between rating life, load rating, and load is:

L10 = (C/P)3 with L10 = rating life (106 rev)

C = basic dynamic radial load rating (lbf)

P = equivalent radial load (lbf)

To obtain the rating life in hours, use:

L10 hrs = 16667/N * (C/P)3 with N = speed (rpm)

The Equivalent Radial Load is defined as:

P = XFr + YFa with

Fr = radial load (lbf)

Fa = axial load (lbf)

X - see below

Y - see below

Radial Contact Bearing Calculations

For radial contact bearings calculate P with X = 1 and Y = 0. Then recalculate P with X = 0.56 and

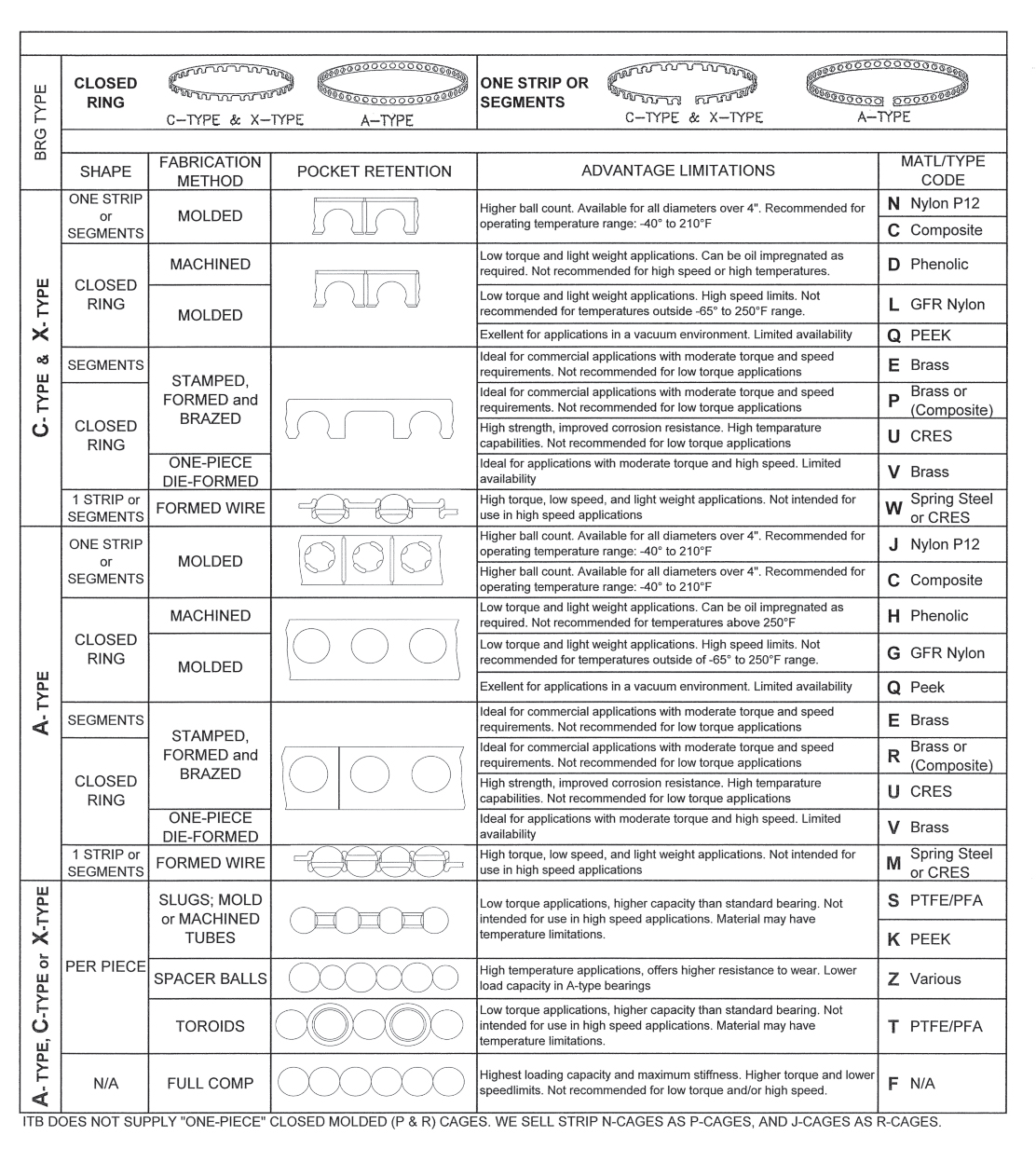

Y = (see chart below). Use the larger value of P to determine L10 life.

n = number of balls

d = diameter of balls (in.)

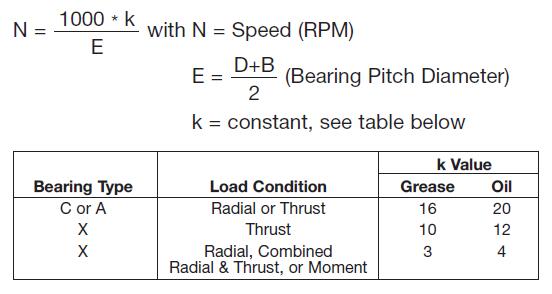

Load and Speed Limitations

The load ratings shown in the product tables are not additive. For combined simultaneous loading, an

equivalent radial or thrust load must be considered. In general, C-Type bearings are designed for radial loading applications; moderate thrust and/or moment loading may be applied in combination with radial loading. For thrust loading applications use the A-Type bearing; any radial loading should only be applied in combination with thrust loading. X-Type bearings are primarily for reversing thrust and moment loading, pure radial loading should not be applied.

Lubrication

Lubricants serve a number of very important purposes in ball bearings, including:

• protecting bearing surfaces from corrosion

• reducing rolling and sliding friction

• preventing metal-to-metal contact between balls and raceway

• providing a barrier against external contaminants (grease)

• removing heat (oil)

Lack of lubrication or inadequate lubrication is the most common cause of bearing failure.

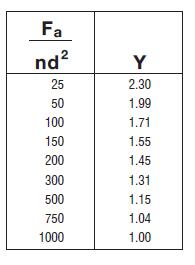

Standard Thin Section Ball Bearings are lubricated with either oil or grease. The unsealed bearings, the K

series, are thoroughly coated in oil and drained of excess. Sealed bearings are lubricated with grease. The external surfaces of sealed bearings are lightly coated with the same grease for corrosion resistance. Additional lubricants are also available. Our Engineer can help select the appropriate lubricant for special applications.

Temperature

Standard Thin Section Ball Bearings can operate at temperatures from -65°F to 250°F. Temperatures up to 350°F can be reached if the bearings are temperature stabilized. By the use of special materials can provide bearings for operation to 900°F. Contact your Monton Sales Engineer for recommendations on bearings operating above 250°F.

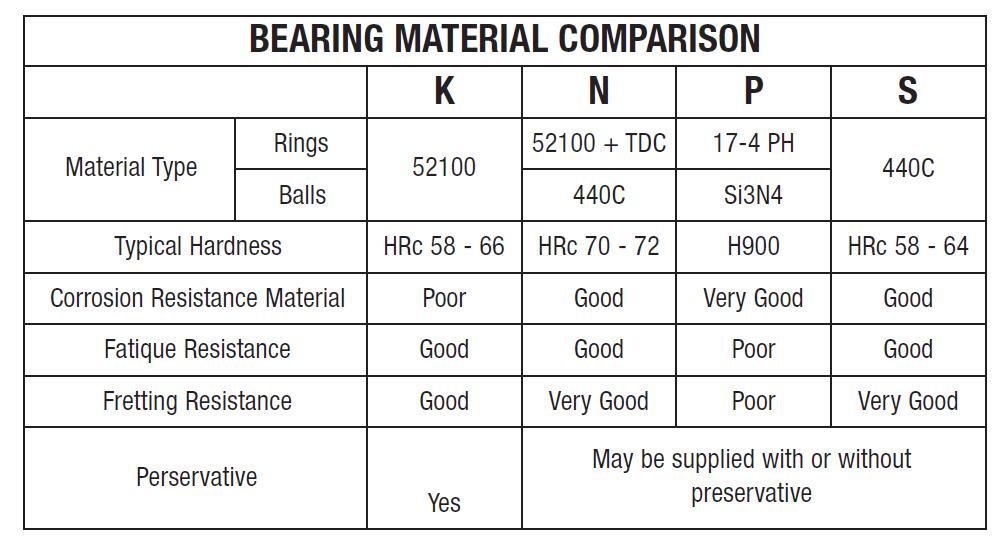

Limiting Speed

The limiting speed of a bearing is dependent upon a number of different factors including bearing size,

bearing type, ball separator design, lubrication and loading. The limiting speeds for the bearings shown in

this catalog are determined using the following:

The k values shown give the maximum speeds at which a typical thin section ball bearing can operate. It is

recommended that operating speeds of large diameter bearings in a given series be reduced up to 40% of the calculated rating to avoid high bearing temperatures.

Speed ratings can also be impacted by load conditions, lubrication, alignment and ambient temperature. All of these factors must be considered when designing thin section ball bearings into your application.

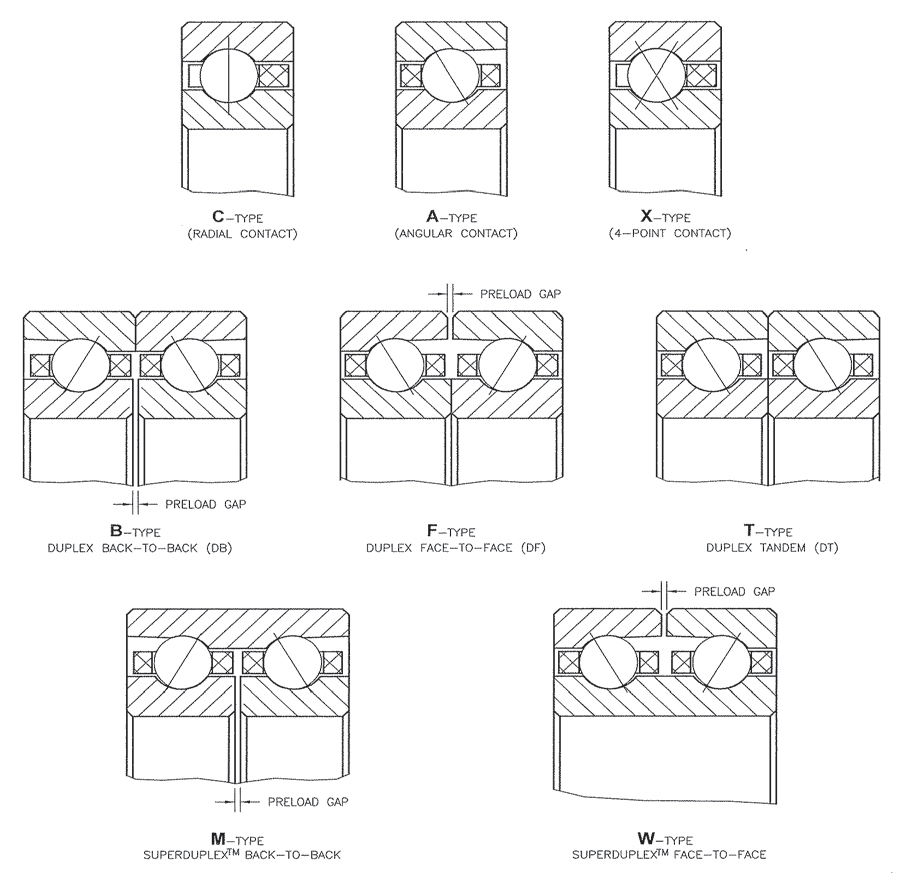

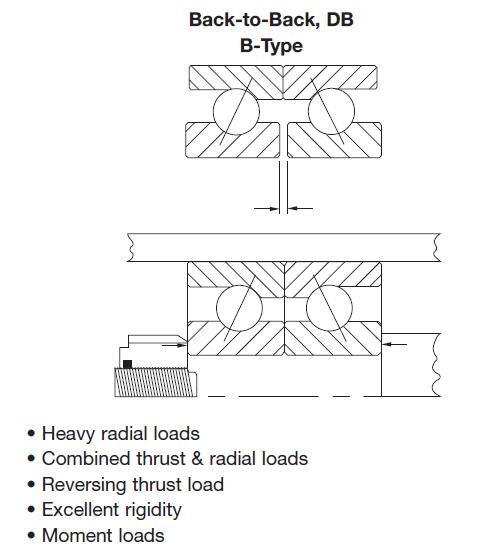

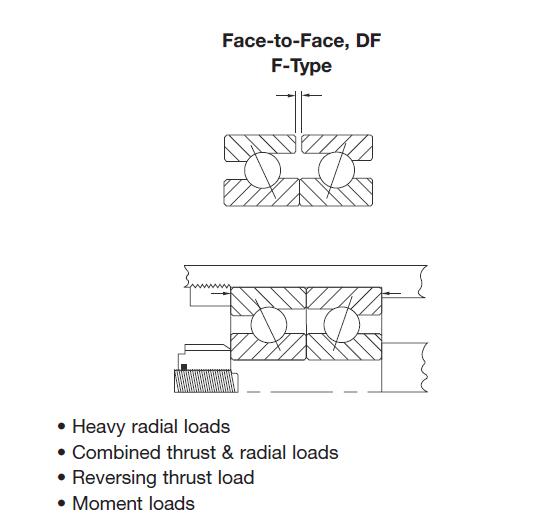

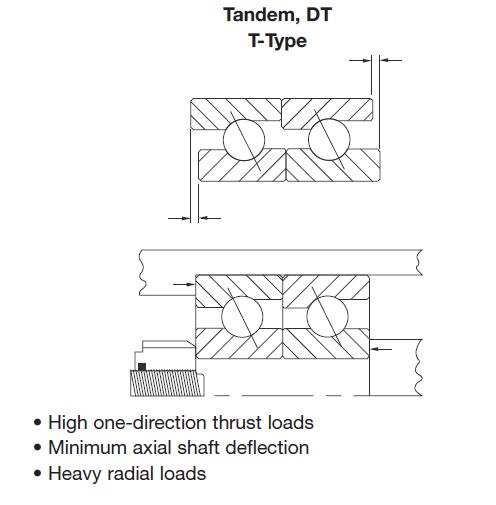

DUPLEX PAIRS AND AXIAL PRELOADING

Duplex Pairs

Duplex bearings are a pair of angular contact Thin Section Ball Bearings specially ground for use as a

matched set. A duplexed pair can be used to provide accurate shaft location, to increase capacity or to

increase stiffness of the bearing assembly. A duplex pair of Thin Section Ball Bearings is ground so that

when mounted using recommended fits, there will be nointernal clearance in the bearings. There are three basic mounting methods to accommodate different loading requirements:

• Back-to-Back (DB), B-Type

• Face-to-Face (DF), F-Type

• Tandem (DT), T-Type

Axial Preloading

Standard duplex bearings are ground so that there will be a light axial preload induced on the bearing at

nominal conditions. In some applications increased bearing stiffness may be required. In these cases the

duplex grinding can be done such that a heavier axial load is induced in the mounted bearing. This load can be increased or decreased to meet the requirements of a particular application. Consult our Sales

Engineer for special requirements.

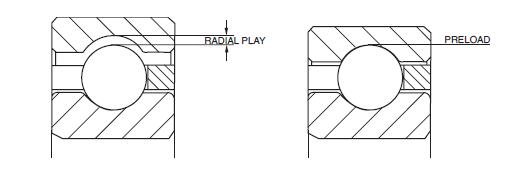

Radial Play

Radial play (diametral clearance) is the distance the inner ring can be moved radially from one extreme position to the other. Standard Thin Section Ball Bearings are manufactured with enough radial play that some clearance remains after the bearing is properly installed.

When there is negative radial play (diametral preload) there is interference rather than clearance between the balls and the races. As the interference increases, the friction, stiffness and torque also increase. Thin Section Ball Bearings can be manufactured with customer specified diametral preload or clearance.

Radial and Axial Runout

Radial runout of Thin Section Ball Bearings is a measurement of the thickness variation of the bearing

rings. The outer ring is measured from the ball path to the outer diameter of the ring, the inner ring is measured from the ball path to the bore. Radial runout is defined as the wall thickness variation of the rotating ring. Axial runout is measured from the ball path to the face of the bearing rings. The variation in thickness measured is the axial runout.

TOLERANCES

Precision Grades

Thin Section Ball Bearings are available in four precision grades. Precision classes P0, P5 and P6. Correspond to ABMA ABEC grades 1F, 3F, 5F and 7F respectively. The tolerances for the bearing bores, outer diameters, radial runouts, axial runouts and radial plays please contact our sales engineer.

Thin section ball bearings are generally used in applicationswith space, weight, and load con straints. Some typical applications for standard Thin Section Ball Bearings include:

Medical Equipment Machine Tools Radar Equipment Textile Machinery

Material Handling Satellite Systems Antenna Pedestals Packaging Ma chin ery

Aerospace Scanning Equip ment Optical Equipment Semi-Conductor

Rotary Joints Manufacturing Equipment Military Turrets Slip Ring Assemblies

Robotics Harmonic Drives Speed Reducers